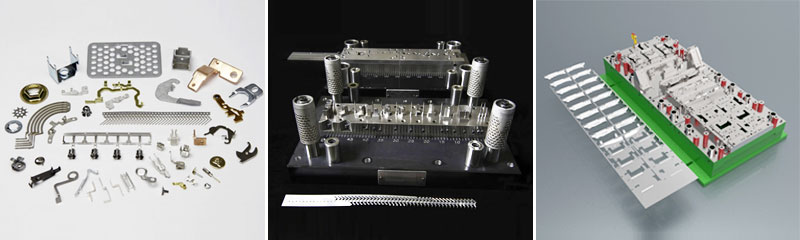

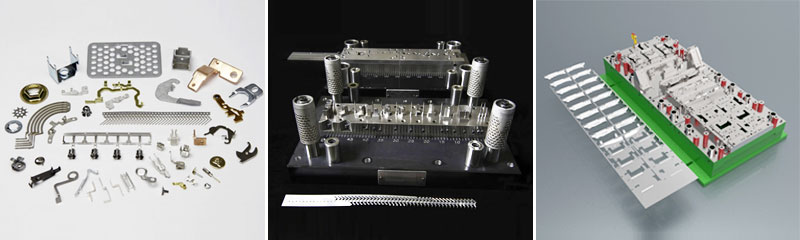

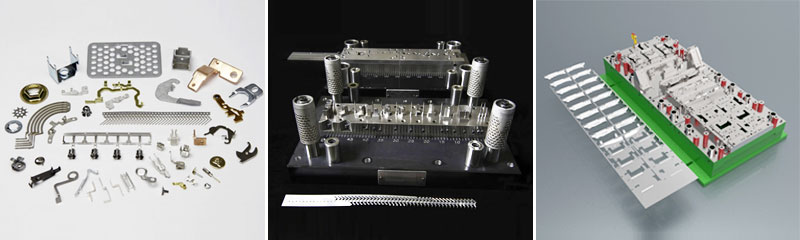

Progressive Die Stamping is a cutting and forming process that utilizes a “Die” that contains a series of stamping stations to perform simultaneous operations on sheet metal that has been supplied on coiled strip. The final metal work piece is developed as the strip of metal is processed through the stamping die. This transformation is performed incrementally, or progressively, by a series of stations that cut and form the material into the desired shape. A Progressive Stamping Die ("Die") is a metalworking device that is designed and built to convert a flat strip of metal raw material into completed parts which conform to print specifications.

The benefits of utilizing the progressive die stamping process characteristically include:

The ability to utilize of multiple cutting and/or forming operations simultaneously

Excellent suitability to produce components at a rapid rate

The ability to produce two or more parts per press stroke

Quick set-up

Ability to maintain control of part location throughout stamping process

The capability to maintain consistently close tolerances

High press tonnage