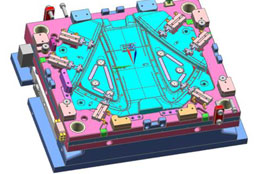

Using software like COPRA FEA ROLL FORM from Germany for our engineers.

Developed almost 3000 profiles of sliding rail, guide rail, and trim parts successfully.

Mastery of high strength plate rolling and 3D roll bending.

Development of the entire roll forming line independently, including rolling after piercing holes and TIG welding after rolling on-line.

Mastery of variable section extrusion craftsmanship, whose maximal variation is 18mm.

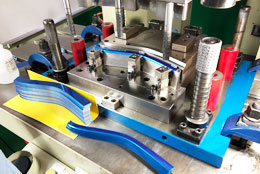

Own co-extrusion technology: Metal (Stainless/Fe/Aluminum/PVC/TPE/TPV); Pure Extrusion ( PVC / TPE / TPV / PP / CPVC / Cu / Fiberglass ).

Own 3D bending, roll bending, and top bow technology.

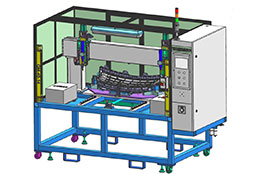

Capable of developing various customized bending machines.

Rich bending experience of stainless steel and aluminum.

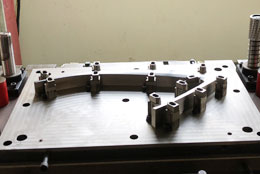

Widely use of DYANFORM CAE analysis software.

Mastery of bright surface stamping technology.

Mastery of B Pillar cover progressive stamping technology.

Mastery of custom stamping machine development.

The designated supplier of Shanghai General Motor.

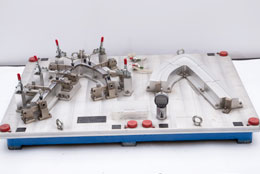

Rich fixture design experience for Toyota, Honda, GM, Nissan, BMW, Diamler, etc.

Mastery of digital fixture technology, which can achieve date automatic detection, collection, and SPC analysis.

Own gas-assisted and dual color (double based) injection molding technology.

Widely use of MOLDFLOW for CAE Engineering analysis.

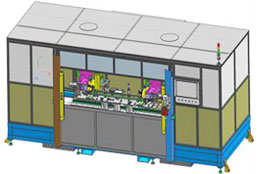

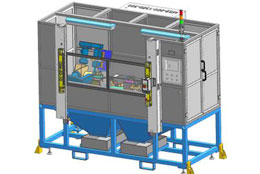

Capable of developing various kinds of automatic production line and special machine, whose process includes sawing, assembly, milling, welding, drilling, etc.

Mastery of robot drilling, sawing, polishing, removing, assembly, etc.

Own export license for roll forming machine, cut-off machine , sewing machine, hydraulicpunching machine, combined special machine, etc.